Mechanical Sealing Products

Find the perfect sealing solution for your applications. View some of our mechanical seal selections below.

Experience Confidence in Your Sealing Solutions

Ergoseal provides high-quality mechanical seal solutions designed for reliability and confidence.

- Comprehensive Offerings: We supply everything from standard equivalent seals to fully custom engineered solutions.

- Variety of Seal Types: Our product range includes circumferential seals, component seals, metal bellows, and OEM replacements.

- Quality Craftsmanship: Seals are meticulously crafted to guarantee superior quality and performance.

- Focus on Durability: Engineered for safety and longevity in demanding applications.

- Customer Assurance: We deliver the confidence you are receiving the best sealing solution for your needs.

Circumferential Seals

Windback

FEATURES

- Zero power dissipation

- Windback seal utilizes shaft boundary layer to seal process oil or gas.

- Gas purge option.

- Typical uses include vacuum pumps, blowers, compressors, and other rotating equipment

Carbon Solid

FEATURES

- Retainer utilized for axial sealing inside the groove.

- Non-contacting, segmented,self-aligning carbon rings for controlled leakage.

- Face load 50-75% less than spring seal

- Short axial length

- Reduced friction on seal face lowers heat and wear resulting in longer seal lifespan

PARAMETERS

- Pressure: Vacuum to +290 psi abs

- Temperature: -184 ̊F to +400 ̊F

Carbon Split

FEATURES

- Retainer utilized for axial sealing inside the groove.

- Split housing for easy installation

- Non-contacting, segmented, self-aligning carbon rings for controlled leakage.

Parameters

- Pressure: Vacuum to +290 psi abs

- Temperature: -184˚ F to +400˚ F

- Speed

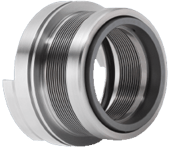

Component Seals

Type 10

FEATURES

- Used for the high-speed applications

- Can be balanced without having to undercut the shaft

- Typical applications include gear boxes, pumps, compressors, and mixers

Parameters

- Pressures: Up to 25 psi ID and 350 psi OD

- Temperature: Up to 500°F

- Speed: 20,000 sfpm

Type 11

FEATURES

- Used when application presents excessive ID pressure

- Typical applications include gear boxes, pumps, compressors, and mixers

Parameters

- Pressures: Up to 250 psi ID and 350 psi OD

- Temperature: Up to 500°F

- Speed: 20,000 sfpm

Type 14

FEATURES

- Fully machined

- Heavier construction

- Built for higher pressure applications than Type 11

- Typical applications include gear boxes, pumps, compressors, and mixers

Parameters

- Pressure: Up to 1200 psi

- Temperature: Up to 500°F

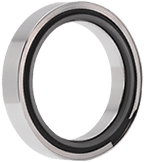

Metal Bellows Seals

Type 100

-

Features

- Rotating bellows

- Metal bellows acts as both a spring and hermetic secondary seal

- Can be constructed from any weldable material

- Can be designed to be compatible wtih nearly any media

- For unstepped shafts

- Balanced

- Independent of direction of rotation

Parameters

- Pressure: 375 psi [25 bar] max

- Temperature: -40 to 800 °F [-40 to 425 °C]

- Speed: 5000 fpm [25 m/s] max

- Typical Applications: gearboxes, fixed and rotary wing aircraft, process pumps, compressors, and other rotating equipment.

Type 110

Features

- Stationary bellows

- Metal bellows acts as both a spring and hermetic secondary seal

- Can be constructed from any weldable material

- Can be designed to be compatible with nearly any media

- For unstepped shafts

- Balanced

- Independent of direction of rotation

Parameters

- Pressure: 375 psi [25 bar] max

- Temperature: -40 to 800°F [-40 to 425 °C]

- Speed: 5000 fpm [25 m/s] and beyond - max speed determined by application pressure-velocity (PV)

- Typical Applications: gearboxes, fixed and rotary wing aircraft, process pumps, compressors, and other rotating equipment

Who We Work With

At Ergoseal, we are proud to partner with companies that demand high-performance seals and sealing solutions. Our expertise is best suited for organizations with large-scale production and complex engineering requirements.

Our customers include:

✔ A broad range of industries including industrial OEMs, aerospace, government, and pool & spa companies

✔ Businesses with at least $50M in annual revenue

✔ Procurement and engineering professionals, including supply chain managers, design engineers, and commodity managers

✔ Companies primarily based in North America, with an expanding presence in Europe

Have a seal project? We can help.

For over 35 years, Ergoseal has been a trusted supplier of high-quality sealing solutions, earning Preferred Supplier Status with leading global brands. We design and manufacture seals ranging from drop-in replacements to fully customized options.

Let our experts help you find your perfect solution today.

© Ergoseal, Inc • Cage Code 1L0H7 • 346 Commerce Drive, Carol Stream, IL 60188 • +1-630-462-9600 • www.ergoseal.com