Component Seals

Ergoseal offers a wide range of seals for a variety of uses. From standard, off-the-shelf products to custom-designed seals specific to your project or application, we can find the optimal sealing solution for your needs.

Seal Types

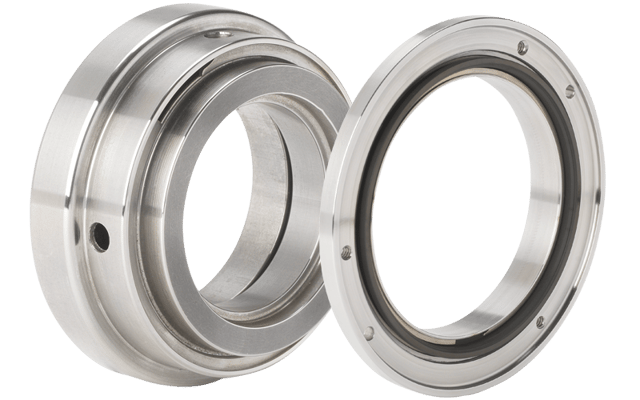

Type 10

Stationary seals used for a variety of high-speed applications where axial space is limited.

FEATURES

- Used for the high-speed applications

- Can be balanced without having to undercut the shaft

- Typical applications include gear boxes, pumps, compressors, and mixers

Parameters

- Pressures: Up to 25 psi ID and 350 psi OD

- Temperature: Up to 500°F

- Speed: 20,000 sfpm

Type 11

Similar to a Type 10, this aircraft style seal includes a ferrule behind the O-ring for ID pressure.

FEATURES

- Used when application presents excessive ID pressure

- Typical applications include gear boxes, pumps, compressors, and mixers

Parameters

- Pressures: Up to 250 psi ID and 350 psi OD

- Temperature: Up to 500°F

- Speed: 20,000 sfpm

FEATURES

- Fully machined

- Heavier construction

- Built for higher pressure applications than Type 11

- Typical applications include gear boxes, pumps, compressors, and mixers

Parameters

- Pressure: Up to 1200 psi

- Temperature: Up to 500°F

- Speed: 15,000 sfpm

FEATURES

- Unitized seat and seal make for easy assembly

- Typical applications include pumps, mixers, and compressors

Parameters

- Pressures: Up to 250 psi ID and 350 psi OD

- Speed: 10,000 sfpm

-

Temperature: Up to 500°F

Type 20

Types 20 seals feature chemically inert materials on every surface that comes into contact with the liquid being sealed.

FEATURES

- Maximum corrosion resistance

- Independent spring assembly

- Prevents seal face misalignment

- Easy removal & replacement of components subjected to the most wear

- Typically used in process pumps

PARAMETERS

Pressure: 150 psi

Temperature: -50°F to 250°F/-45°C to 121°C

Speed: 1000 fmp/5 mps

Custom solutions

While OEM seals suffice for some applications, many use cases require custom sealing solutions.

Whether you need a seal that meets specific performance requirements or can withstand extreme operating conditions, Ergoseal offers the in-house design and rigorous testing expertise to ensure your custom seal meets your precise specifications and performs in even the most demanding environments.