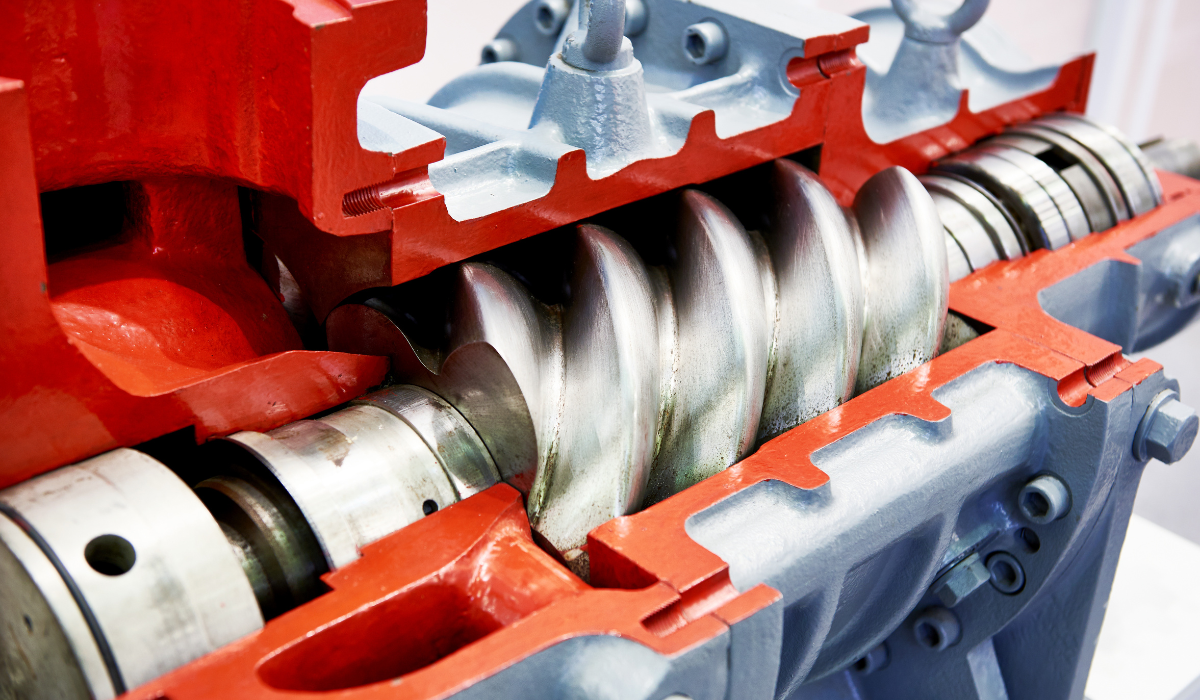

Rotary Seal Solution Increases Compressor Efficiency and Seal Life

Overview

A global manufacturer of rotary screw compressors turned to Ergoseal to improve the durability and efficiency of its sealing systems. The company’s Value Analysis/Value Engineering (VAVE) team was seeking a solution that would reduce leakage, extend service life, and minimize costly field maintenance. Ergoseal delivered a custom rotary seal solution that significantly improved performance, extending seal life from 15,000 to over 40,000 hours — and positioned the client for long-term reliability and cost savings in demanding industrial applications.

VAVE IS A SYSTEMATIC APPROACH

used in product development and manufacturing to improve the value of a product or process by either increasing its function or reducing its cost, without compromising on quality or performance.

Gerald Strenk • Global PTFE Product Manager, ErgosealReducing Leakage, Improving Efficiency, and Extending Seal Life

Rotary screw compressors rely on continuous, high-volume air compression, and even minor leakage in the sealing system can lead to significant energy loss, pressure drops, and increased maintenance.

For many compressor OEMs, it's typically the VAVE teams that drive sealing decisions — seeking efficiencies, longer component life, and reduced field maintenance. Seal replacement in the field is difficult and costly, so increasing longevity was a major priority.

The client was evaluating new strategies for minimizing leakage, comparing traditional sealing options such as PTFE, labyrinth, and mechanical face seals. They also sought to reduce downtime, enhance efficiency, and ensure long-term reliability in demanding industrial environments.

Higher Efficiency, Lower Maintenance, and Improved Reliability

The implementation of the custom rotary seal led to measurable improvements in compressor efficiency and reliability:

-

Reduced leakage and energy loss

-

Improved oil retention in oil-flooded models

-

Extended seal lifespan, reducing downtime and maintenance costs

-

Enhanced overall system reliability in continuous-use industrial environments

Most notably, the solution helped increase the expected seal life from approximately 15,000 hours to over 40,000 hours — a dramatic improvement that directly supports the VAVE team's long-term goals.

.png?width=600&height=350&name=ERGOSEAL%20Rotary%20Screw%20Compressor%20Case%20Study%20June%202025%20(1).png)

We optimized the seal through its materials and function

to extend the life of the seal before replacing from 15,000 hours to 40,000 hours. This means fewer service disruptions and more value across the product's lifecycle.

Have a project? Tell us how we can help.

Our seal design and engineering department have expertise in a wide variety of sealing solutions to help you find your perfect solution.