Why PTFE Seals Are a Smart Choice for Compressors

Looking for longer-lasting, higher-performing compressor seals?

PTFE might be the upgrade your system needs — with unmatched chemical resistance, temperature stability, and efficiency gains. Here’s why engineers are making the switch.

In This Blog:

- The Challenge: Demanding Compressor Environments

- Why PTFE Performs So Well in Compressors

- Real-World Applications

- Performance Life, Efficiency, and Reliability — Why PTFE Outlasts

- Tailored to Your Application

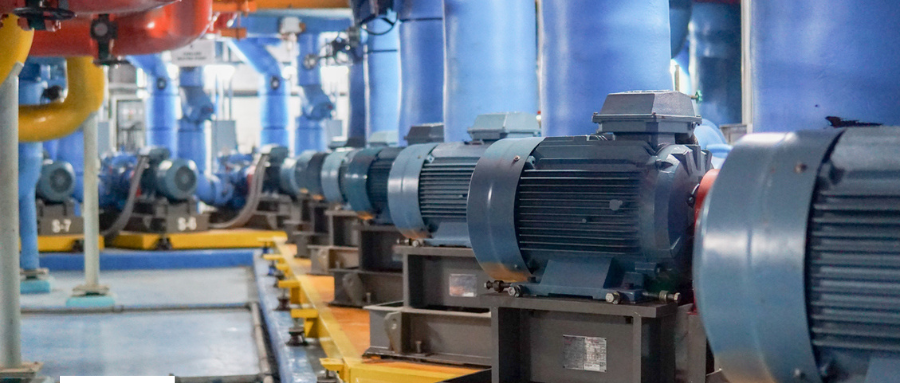

Compressors are the workhorses behind countless machines and systems — from air conditioning and refrigeration to aerospace equipment, oil and gas systems, and even high-performance food processing equipment. But no matter the application, one thing remains true: when compressor seals fail, everything comes to a halt.

That’s where PTFE (Polytetrafluoroethylene) seals come in.

The Challenge: Demanding Compressor Environments

Compressors often operate under extreme conditions, such as:

- Wide temperature fluctuations – from cryogenic lows to sustained, high heat

- Exposure to harsh chemicals, refrigerants, or lubricants

- Continuous operation

- High cycling

- Low friction and long seal life requirements

Using the wrong seal can lead to energy loss, equipment downtime, or costly maintenance cycles. PTFE offers an advantage across all these fronts.

Performance Life, Efficiency, and Reliability — Why PTFE Outlasts

For compressor manufacturers, reliability isn’t just a buzzword — it’s a bottom-line concern. Downtime, warranty claims, and field replacements all eat into margin and customer trust. That’s where PTFE stands out.

“PTFE is an awesome solution in all industries,” said Gerald Strenk, PTFE product manager at Ergoseal. “But if I were a compressor product line manager, I would be most concerned with warranty claims and performance or life that leads to efficiency.”

With PTFE, you’re not just getting resistance to chemicals or a broad temperature range — you’re getting the ability to optimize seal life and extend the number of operating hours a system can run without failure.

“With PTFE, we can optimize the life of the seal and extend it, achieving extended run hours over time,” Strenk said.

And as manufacturers and operators come under increasing pressure to meet energy efficiency goals, PTFE can play a direct role in helping them get there.

“There are programs out there where they are required to meet specific energy efficiency standards,” he said. “We can do that with PTFE that has a lower coefficient of friction. This creates less drag and draw on the systems.”

PTFE’s low friction doesn’t just make systems more efficient — it reduces wear, lowers heat generation, and allows the seal to operate at higher PV (pressure × velocity) values.

“Because of the robustness of PTFE, it is able to run in many tough media like refrigerant, oils, etc.,” Strenk said. “Tied to that robustness, PTFE can see higher PV values. That means it can run at higher surface speeds and pressures.”

PTFE also delivers a complete solution in terms of temperature stability, performance in harsh environments, and overall ROI — especially when compared to elastomers.

“From a cost standpoint over an elastomer, it’s an overall value to the product line because there are no mold costs, problems with media and temperature compatibility, issues with higher friction, lower surface speeds and pressures, and less life — causing the customer to replace seals more often in the field,” he said. “Overall, better reliability!”

At Ergoseal, that performance foundation is further elevated through custom engineering and deep application expertise.

“With that comes Ergoseal, and we take all that and add value by offering detailed application assistance by optimizing that seal for a perfect fit,” Strenk said. “We don’t really sell seals; we sell solutions to a problem.”

The strength of PTFE doesn’t come from one feature — it’s the combination of properties that make it a go-to for compressor environments where failure simply isn’t an option.

Why PTFE Performs So Well in Compressors

PTFE’s unique combination of properties makes it an ideal choice for compressor applications:

- Chemical Resistance: PTFE is virtually non-reactive. It handles refrigerants, oils, solvents, and corrosive gases without degradation — making it a reliable option for chemical processing, HVAC, and industrial gases.

- Wide Temperature Stability: PTFE performs across a broad temperature range (-450°F to 620°F), ideal for compressors in aerospace and cryogenic applications.

- Low Friction & High Wear Resistance: PTFE’s low coefficient of friction minimizes energy loss and wear — boosting efficiency and seal longevity.

- Electrical Insulation: In applications where conductivity must be controlled, PTFE’s naturally low conductivity provides additional reliability.

- Fast Prototyping: Unlike rubber or elastomeric seals, PTFE seals are machined from billet, eliminating tooling requirements and enabling rapid turnaround for prototypes and small runs.

Real-World Applications

PTFE seals are used across compressor systems in industries where failure is not an option:

- Oil & Gas Compression: In harsh upstream environments, PTFE seals withstand aggressive chemicals and high pressures, supporting reliable, leak-free performance.

- Aerospace Cryogenic Systems: PTFE’s extreme temperature range makes it ideal for aerospace compressors exposed to wide thermal swings and mission-critical reliability requirements.

- Refrigeration & HVAC: In commercial and industrial systems, PTFE delivers long life, chemical resistance to refrigerants, and efficiency under constant cycling.

- Industrial Air Compressors: Facilities running high-speed, continuous-duty compressors benefit from PTFE’s low wear and friction for lower energy use and longer maintenance cycles.

These are just a few of the environments where PTFE helps safeguard equipment performance and extend service life — while minimizing downtime and maintenance costs.

Tailored to Your Application

PTFE’s performance can be further optimized by blending in fillers such as carbon, graphite, glass, bronze, and more — each offering specific benefits for:

- Wear resistance

- Heat dissipation

- Load capacity

When engineered correctly, these PTFE composites deliver outstanding, application-specific performance in even the harshest compressor environments.

The Bottom Line

Whether you're designing for aerospace, refrigeration, chemical processing, or industrial manufacturing, PTFE seals offer reliability where it matters most: sealing performance, energy efficiency, and equipment uptime.

Explore our PTFE capabilities and see how we help teams like yours get it right the first time. Get in touch with us today!

.png)

.png)

.png?width=352&name=Materials%20Matter%20Aero%20Blog%20Jan%202026%20(1).png)